Under what load should the generator be tested?

Before we talk about DPF cleaning equipment, let's remind you why you need a diesel particulate filter in the first place, and how it's fundamentally different from a catalytic converter. This information may seem redundant, but it's the key to understanding why the particulate filter needs to be cleaned from time to time, and why it's best done with a diesel particulate filter cleaning machine.

It's true that the catalytic converter (or catalyser, as it's often abbreviated) and soot filter have a lot in common – both of these devices protect the air from harmful impurities in the exhaust and are superficially similar. However, firstly, as you can already understand from its English name, the particulate filter is used mainly on diesel cars (DPF – diesel particulate filter).

And secondly, their purpose is different: the catalytic converter cleans toxic gases, processing harmful substances into harmless ones, and the particulate filter traps soot particles formed as a result of incomplete combustion of diesel fuel. And the main difference is that DPF-equipped engines require regular cleaning.

Particulate Filter Cleaning System

Regeneration, or self-cleaning of the particulate filter occurs in two main scenarios: it is either burning out the soot residue from the filter by raising the temperature of the exhaust gases to 600-800 °C (more common on German cars), or using a special liquid that helps the soot burn out without raising the temperature (French system). Cleaning of the car's DPF is started by the control unit based on sensor readings. If they detect a too large pressure difference between the pressure before and after the filter, forced regeneration must be switched on.

But this is ideal, in practice there are too many additional requirements the car must fulfil to clean the DPF while driving. The ECU will not command regeneration to take place if:

- the fuel tank is low on fuel;

- the EGR valve is defective or clogged;

- sensors or their wiring is faulty;

- exhaust gases have not had time to warm up sufficiently

The latter is especially true for those cars that are mainly operated in large cities. In such cars, the conditions for cleaning the DPF filters in the normal mode may not develop for years, even though ideally the regeneration process should be switched on after a maximum of 5000 kilometres of mileage – this is if the diesel fuel is of very high quality, which is not always the case.

Regeneration process should be switched on after 5000 kilometres of mileage.

But only in the case of constant self-cleaning there is a chance that DPF will last 150-180, or even more, thousand kilometres on a diesel car without replacement or removal, which is very often resorted to by diesel car owners because of the price of new particulate filters. In this case it is necessary to remove the catalyst, which automatically deprives the car of even a hint of environmental friendliness and sometimes leads to problems with regulatory authorities.

A diesel particulate filter cleaner as an alternative to replacement

In general, cleaning DPF filters is not a new technology, it has been used for quite a long time. And, unfortunately, not only at certified service stations, but also in garage conditions. The thing is that the regeneration process, even if it starts in normal mode, does not always suit car owners, because it is associated with increased fuel consumption. In this case, the equipment for washing the particulate filter, if we can put it this way, are cans with auto-chemicals sold in online shops.

There are two ways to fill the particulate filter:

Besides the dubious result, such a system for filter cleaning does not stand up to any criticism because of its blatant unecological nature. The chemical waste products are extremely toxic and can harm not only the environment, but also the participants in the process, because they forget to think about proper disposal, and the waste solution, after leaving the DPF filter cleaning equipment, ends up in the sewer system, where the chemistry dissolves in the wastewater.

Avoiding negative environmental impact can and should be done by acting professionally and using equipment specifically designed for the cleaning process. Such as the MS900 particle filter flushing stand, which is designed to clean the particle filters of all diesel vehicles (DPF and FAP) by flushing them.

The uniqueness of this particulate filter cleaning machine is that it removes deposits without the use of chemical detergents, using only warm water. The MS900 works by periodically reversing the direction of water flow and utilising compressed air pulses to ensure that filters of any degree of clogging are washed properly.

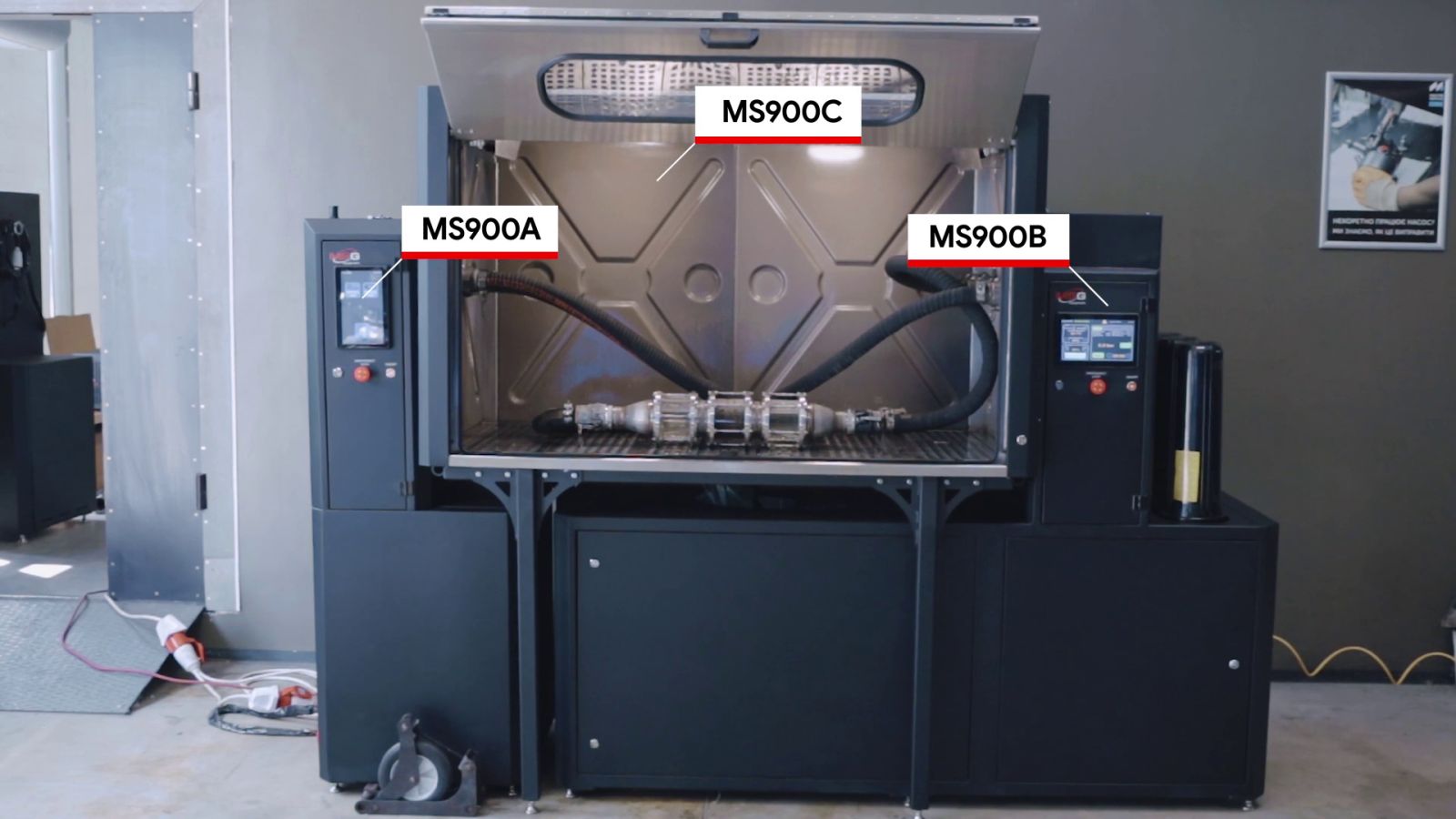

The particulate filter cleaning equipment consists of three modules, each responsible for a different part of the procedure:

Modules A and B can be operated separately from each other, and if the bench is equipped with two MS900Cs, two filters can be serviced simultaneously. This feature makes the MS900 a unique machine for cleaning DPF filters for sale at the service station.

There are other important advantages of the bench:

We believe that all of the above allows us to say that the MS900 is the best DPF cleaning machine on the world market of professional equipment.

- In the dismantled filter, closing the outlet hole.

- By unscrewing the pressure or temperature sensors and inserting a probe into the hole.

- MS900A – diagnostic and drying module;

- MS900B – flushing module;

- MS900C – washing and drying chamber.

- possibility of repeated water reuse;

- compactness of installation and easy mounting of modules;

- versatility of equipment and flexibility of software;

- storage and printing of particulate filter cleaning results.