Efficiency of soot filter cleaning with the ms900 stand compared to other methods

Mankind is becoming increasingly aware of the importance of caring for the environment, which is why environmental requirements are becoming more and more stringent. Since Euro-4 standards came into force in 2005, all diesel cars have had to be fitted with particulate filters. However, what is beneficial does not always make life easier for ordinary people. The particulate filter has become an integral part of the car and therefore it is necessary to know how to fix problems with it.

What is a particulate filter and what are the possible problems?"

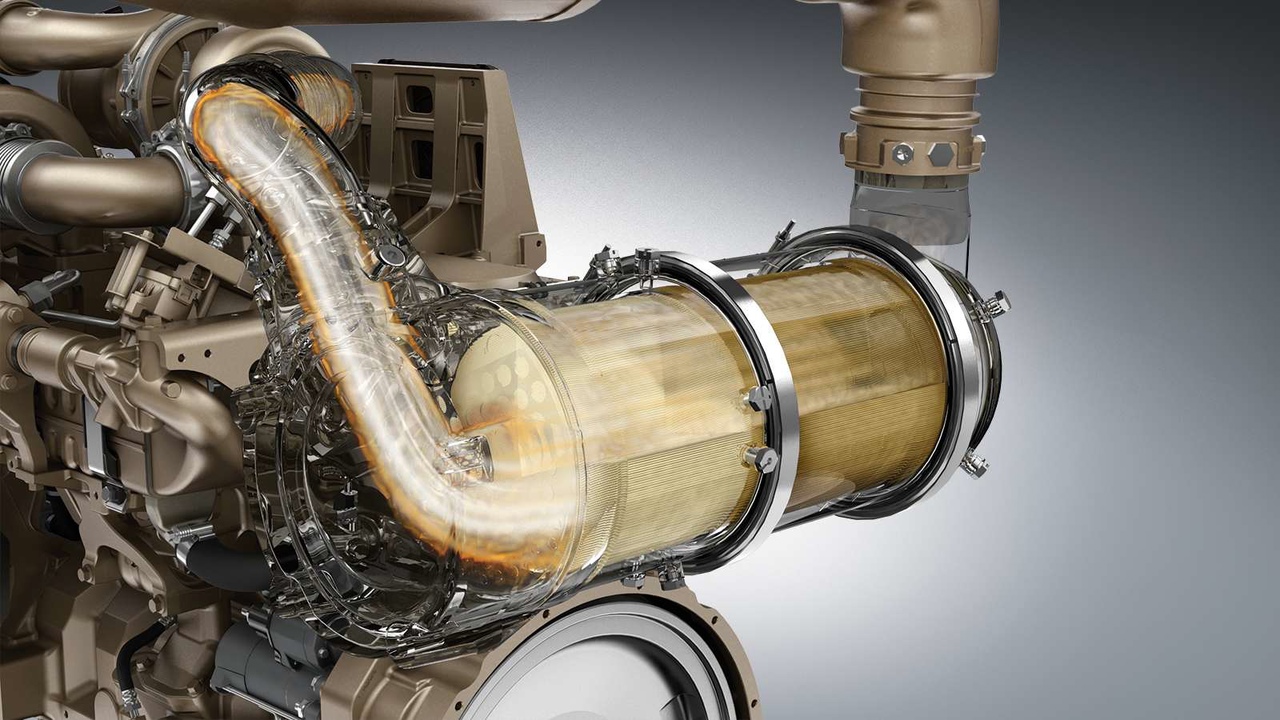

The main danger that diesel cars pose to the environment and people is the large amount of soot that is found in the exhaust gases. Soot – these are small particles of graphite into which unburned carbon atoms are clumped. It is as harmful to breathe them as coal dust. The task of the filter – to catch it. However, because a diesel engine produces a lot of soot, the filter fills up quickly. That is why every diesel particulate filter (Diesel Particulate Filter) has the possibility of self-cleaning – regeneration. Self-cleaning of the particulate filter is switched on by the command of the car ECU and goes unnoticed by the driver.

There are two types of regeneration depending on the design:

1) Heating the exhaust gas to 600-8000C. It is used in autos where the filter is installed next to the exhaust air duct. This system is usually called DPF, which is not quite right.

2) Combustion at lower temperatures with the help of cerise-containing additive. This system is predominantly used in French cars, where the filter is placed in the middle of the exhaust system, so it is often called FAP – «filtre a particules».

The disadvantages of both options are that minor engine faults can block the regeneration process. Self-cleaning of the particulate filter may also fail if the car is constantly forced to drive in heavy urban traffic. A clogged filter leads to increased fuel consumption, reduced engine power and starting problems.

Since new original parts are very expensive, and there are either no substitutes or they are not of the right quality, car owners are forced to solve the problem by removing or washing the filter. In the first case it is frightening to have to re-flash the car's ECU to lower emission standards, which can cause problems with regulatory authorities. In the second case – uncertainty about the effectiveness and safety of the procedure.

Tools and equipment for cleaning the DPF

All particulate filter cleaning methods have their pros and cons. For example, the ultrasonic method, while undoubtedly effective, is expensive and hardly suitable for lorry particulate filters. Thermal and pneumatic methods can be considered only as stages of a complex of measures.

The chemical method, which is often meant when they say «particulate filter cleaning», against their background looks very effective, but it also has disadvantages due to its technology and materials used. The chemical method of particulate filter cleaning consists in pouring strong chemistry inside the DPF. For this purpose it is not always necessary to dismantle the filter – the filter honeycomb can be soaked with liquid even through the sensor hole. There are two main disadvantages of chemical flushing:

- The blatant unecological nature of the method. The spent liquid is very unsafe not only for the environment, but even for the health of the personnel carrying out the work.

- Chemical flushing is very unsafe.

- The amount of time spent. Duration of «soaking» filter – 8-10 hours.

Although chemistry gives the result, it is impossible to measure the condition of the filter after such washing – unlike professional stands.

The MS900 bench and its main advantages

The MS900 particulate filter cleaning stand developed by us works on a completely different principle. No chemicals are used, unless the DPF needs to be pre-washed of trapped engine oil. The method of cleaning in our stand – combined hydro-pneumatic. The process involves warm water running in a closed cycle and shock impulses of compressed air.

Let's list all the pros of this particulate filter flushing equipment:

- Low cost of washing. It consists only of the cost of electricity and staff salaries.

- Fast flushing. The complete cycle of DPF diagnostics and cleaning lasts no more than 2-3 hours.

- Universality. The stand allows washing filters of any cars, and also works as equipment for cleaning the catalytic converter.

- All the filters can be washed.

- High productivity. The modular design of the MS900 allows to wash and dry filters simultaneously.

- Modular design of the MS900 allows to wash and dry filters simultaneously.

- Convenience and functionality. The processes in our booth are as automated as possible and the results can be saved or printed.

But the main advantage of our particulate filter washing equipment – complete absence of environmental impact, because it can clean the particulate filter to a new condition without the use of special chemicals.