Fast and Efficient DPF Cleaning in service stations

Before discussing DPF cleaning equipment, let's first recall why a diesel particulate filter (DPF) is essential and how it fundamentally differs from a catalytic converter. While this information may seem unnecessary, it holds the key to understanding why periodic cleaning of the DPF is necessary and why it's best done with a dedicated DPF cleaning machine.

Indeed, both the catalytic converter and the DPF share similarities in protecting the air from harmful exhaust emissions and appear externally similar. However, the DPF is primarily used in diesel vehicles (DPF – diesel particulate filter), as indicated by its English name. Moreover, their purposes differ: the catalytic converter cleans toxic gases by converting harmful substances into harmless ones, while the DPF captures soot particles resulting from incomplete diesel fuel combustion. The crucial distinction is that engines equipped with DPF require regular cleaning.

DPF Cleaning System

Regeneration or self-cleaning of the DPF occurs through two main scenarios: either burning soot residues from the filter by elevating exhaust gas temperatures to 600-800 °C (more common in German cars) or using a special fluid that aids in soot combustion without raising the temperature (French system). DPF cleaning is initiated by the control unit based on sensor readings. If the sensors detect a significant pressure difference before and after the filter, forced regeneration should activate.

However, in practice, a DPF cleaning machine must meet several additional requirements while the vehicle is in motion. The Engine Control Unit (ECU) will not command regeneration if:

• the fuel tank is low;

• the EGR valve is faulty or clogged;

• sensors or their wiring are malfunctioning;

• exhaust gases haven't heated sufficiently.

This is particularly relevant for vehicles predominantly operated in large cities. Under normal conditions, DPFs in such vehicles may not undergo cleaning for years, while the ideal regeneration process should occur every 5000 km – if the diesel fuel is of high quality, which is not always the case.

Only with consistent self-cleaning, there's a chance that a diesel vehicle equipped with DPF can last 150-180 thousand km or more without replacement or removal. However, owners often resort to removal due to the high cost of new DPFs. Yet, removing the DPF also entails removing the catalytic converter, depriving the vehicle of any hint of environmental friendliness and sometimes leading to issues with regulatory authorities.

DPF Cleaning Stand as an Alternative to Replacement

DPF cleaning is not a new technology, and it has been used for quite some time. Unfortunately, not only in certified auto services but also in garage conditions. The regeneration process, even when initiated normally, doesn't always satisfy vehicle owners because it is associated with increased fuel consumption. DIY DPF cleaning systems, like chemical aerosol sprays available in online stores, are far from being environmentally friendly.

Fluids are injected into the DPF in two ways:

• Into a removed filter, sealing the outlet.

• By removing pressure or temperature sensors and inserting the probe into the hole.

Aside from the questionable results, such filter cleaning systems face criticism for their blatant lack of ecological soundness. The chemical byproducts are extremely toxic and can harm not only the environment but also the individuals involved in the process. Moreover, the correct disposal of these chemicals is often neglected, and the used solution, once it leaves the DPF cleaning equipment, ends up in the sewage system, where the chemicals dissolve in wastewater.

To avoid negative environmental impacts, it is essential to act professionally and use equipment specifically designed for the cleaning process. One such equipment is the MS900 DPF cleaning stand, designed for cleaning DPFs of any diesel vehicles (DPF and FAP) through a washing method.

The uniqueness of this DPF cleaning machine lies in its ability to remove deposits without using chemical cleaning agents, relying solely on warm water. The MS900 operates by periodically changing the water flow direction and using compressed air pulses, ensuring a high-quality cleaning of filters at any level of clogging.

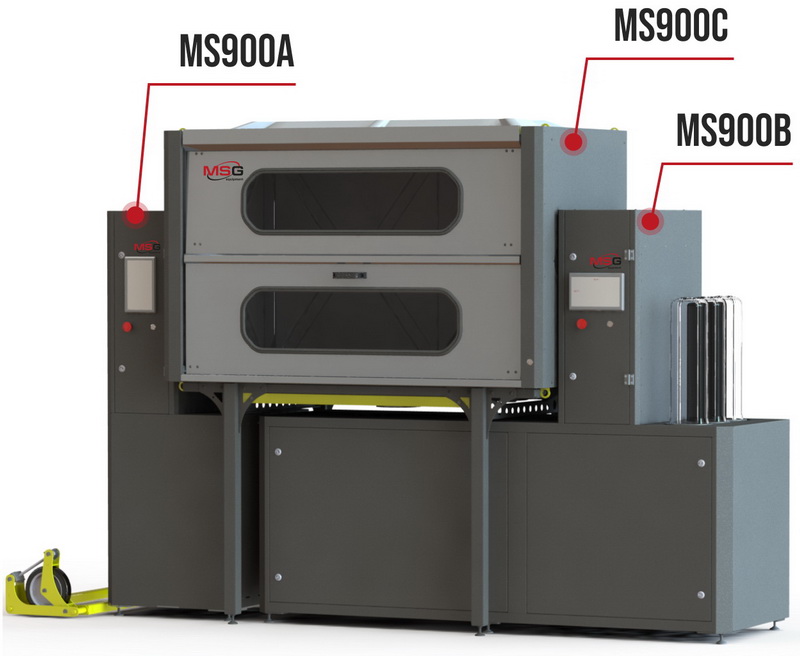

The DPF cleaning equipment consists of three modules, each responsible for its part of the procedure:

MS900A – diagnostic and drying module;

MS900B – cleaning module;

MS900C – washing and drying chamber.

Modules A and B can operate independently, and with two MS900C equipped, two filters can be serviced simultaneously. This feature makes the MS900 a unique DPF cleaning machine for sale in automotive service stations.

Other significant advantages of the stand include:

• the ability to reuse water multiple times;

• compactness of the installation and ease of module assembly;

• equipment versatility and software flexibility;

• preservation and printing of DPF cleaning results.

We believe that everything mentioned above allows us to speak of the MS900 as the best DPF cleaning machine on the global market for professional equipment.