Steering rack assembly. Exterior view and configuration.

The steering enables the vehicles to move to the direction that the driver chooses. The main steering elements: steering linkage and steering mechanism. Nowadays, the car manufacturers install to light engine vehicles the steering mechanisms of rack-and-pinion type where the steering rack is a basis.

To provide the driving with the high level of comfort, the steering rack is equipped with either the hydraulic power steering (HPS) or electromechanical power steering (EPS). There are three main steering rack types:

- Mechanical steering racks.

- Steering racks with hydraulic power steering (HPS).

- Steering racks with electric power steering (EPS).

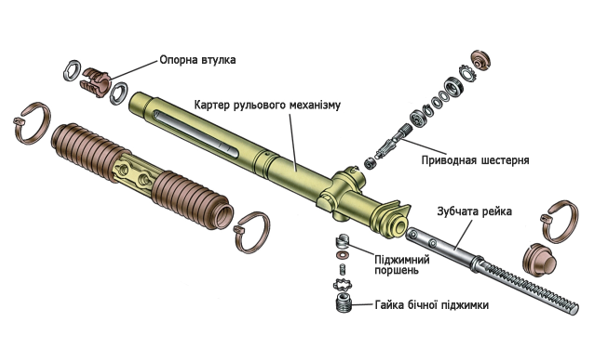

Mechanical steering racks

This type of racks is of the simplest configuration, with the direct gear of torque from the input shaft with pinion to rack. This rack type is commonly used along with EPS, and it’s installed on steering column.

The main components of mechanical steering rack are following:

- Aluminum housing. There’s a specific hollow with the corrugated shield inside - to prevent the mechanism from the moisture and dirt ingression.

- Gear or pinion of drive. It’s located inside the steering mechanism body, and it’s hold there by the special bearing.

- The spring with pressure piston. It presses the steering rack tight to gear. It enables the teeth to gear as tight as possible.

- Bushing designed for tie-rod joint. The bushing operates with the intervals set by the engineers, and also provides the stroke that mechanical rack requires.

Steering racks with hydraulic power steering

The main difference of this rack from the mechanical one - hydraulic cylinders located between tooth rack and body. There’s a sleeve valve installed on the input shaft.

The hydraulic system shall be maintained properly to prevent the leakage of the working liquids and their contamination. To dismount the steering mechanism, the working liquid shall be drained. During the filling the hydraulic system with the fresh working liquid the system has to be deaerated.

This type of racks was widely popular till 2000. Later, there was a transition to the racks with electromechanical power steering. At present time HPS racks are used at off-road vehicles and trucks only. Nearly 98% of all light engine vehicles that are currently manufactured are equipped with EPS.

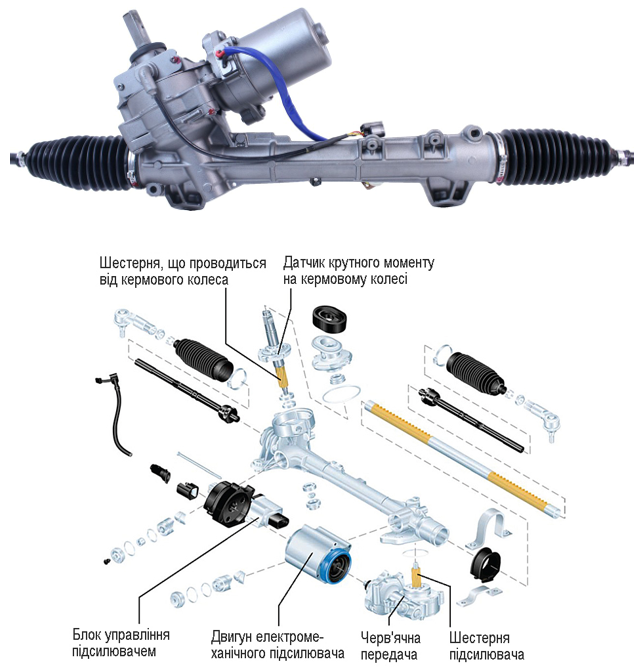

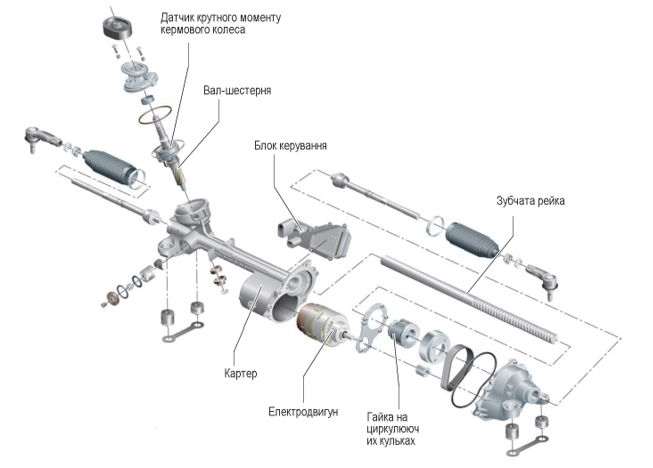

Steering racks with electric power steering

It’s an electric motor that generates the power in this rack types. The electric motor is operated by the electronic control unit system.

There are several EPS rack types with the different methods of the transmission of power to rack rod and control unit positions.

The most widely-used configuration - with the lateral position of electric motor on the rack. The electric motor assists at the moving of the rack through the additional gear and worm gear.

The second configuration - with the electric motor in parallel to the rack, and the power transmission is fulfilled with the toothed belt.

The third option - direct drive. In these rack types, the rod is moved inside the motor by the power transmission provided by the couple “screw-nut”, that’s why the unit assembly is the most compact.

The positions of EPS control units differ and they can be as follows: on the European vehicles, electronic control unit is commonly mounted either close to the electric motor or on it, meaning, on the rack. On the Japanese and Korean car makes, the control unit is mounted closer to the control panel. In the first case, the configuration is easier to maintain, yet the mechanical defects of the control unit may occur as well as the moisture penetration. In the second case, the control unit is better protected. However, if the repair is required one shall disassemble the entire system (pull out several meters of wiring and find the control unit).

Equipment for the steering rack diagnostics

The diagnostics of the steering racks equipped with power steering the special equipment is required:

• Testers for express diagnostics of HPS units without dismounting them from a car: MS610 and MS611.

• Benches for diagnostics of the dismounted HPS units: MS604 tests the single-circuit and two-circuit HPS pumps with mechanical drive; MS502M checks the technical condition of HPS rack, reveals the failures and their mode.

• Multipurpose equipment for HPS units - bench MS603N-220V that checks HPS steering rack and pump without dismounting them from a car, tests steering rack dismounted from a car, enables the flushing of HPS system during the working liquid change.

• Controller MS561 tests the dismounted from a car EPS unit: steering rack, steering column, EHPS pump. Using the controller MS561, one can read the errors from the dismounted steering rack control unit, delete them if required, code or update software.