Specifics of AC system diagnostics

Imagine a situation when we take a car with a faulty (according to the car owner) air conditioning system for repair. What are the first things to look at to get a better idea of what is wrong with the system? What should be the evaluation criteria and signs we should consider? Where should we start?

For starters, we need the car owner to give us as much information as possible. Ask how and when the first symptoms showed up, perhaps something in the system’s behavior draw his attention, when was the last time the system was serviced.

If the information you received didn't shed much light on the situation, then use the following algorithm to perform the diagnostics:

First, check if there is any refrigerant in the system. In case there is, determine the type of the cooling agent and the amount. Weigh the refrigerant as this is the only right way to know the amount. Measuring pressure in the system won't say anything about the amount of refrigerant.

Second, check if there are faults in the ECU that would relate to the AC system. It's important to consider whether the readings of temperature sensors, pressure gauges, and other system components are within normal.

Third, launch the system. It implies bringing the system to steady operation under maximum load. In such a mode, we can objectively assess the system performance. The evaluation parameters include the discharge air temperature at the central air outlet in the cabin. Depended on the ambient temperature, the thermometer should show from 5°C to 10°C. This temperature will be a reliable indicator of the system's performance.

Forth, it is necessary to measure the refrigerant pressure in the system pipelines in different operation modes. The averaged values that depend a lot on the ambient temperature should be as follows: 2 to 4 bars in the low-pressure line and 10 to 15 bars in the high-pressure line.

If the measured values are within the above range when the ambient temperature is 20-25°C, the system can be considered fault-free.

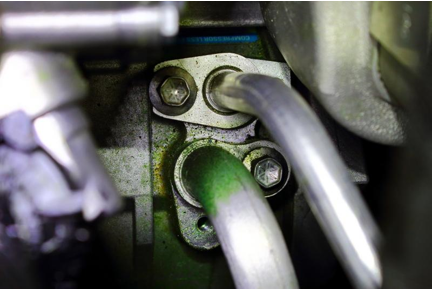

When the diagnostic procedures described in items 1 and 2 have been performed and the trouble identified, we need to find the cause of it. We use an automatic or semi-automatic filling station to measure the amount of refrigerant in the system. If the refrigerant is missing or its amount does not correspond to the norm, there can be only two possible reasons for this - either the system hasn't been filled, or it is leaky. There are many methods for finding leaks (we teach it all at our training courses). The most common one implies the application of a colored die. A fluorescent-colored die is injected into the AC system. After some time, you might see streaks of liquid on the system pipe. If a leak is evident, the colored dye glows brightly. It's easy to pinpoint a leak using this method.

If all the conditions for the system launching have been observed, but it still doesn't start, then the problem may lie in the car electronics. Here testerMS121 can be of help. The tester is intended for direct interaction with the air conditioner compressor, which is the system's heart. Controlling the compressor with tester MS121 will help to exclude the problems with the car electrics.

Everything's done, and still nothing? Then, most probably, the fault cause hides somewhere inside the AC compressor. In such a case, removing the unit from the car and installing it on the specialized test benchMS111 for its comprehensive diagnostics is the best thing to do. This test bench will allow us to simulate the system operation on a vehicle and perform real-time diagnostics of the compressor. A preliminary test of a new or rebuilt compressor before its installation on a car is mandatory: for the first little while, the compressor can pull metal shavings that may "kill" the system.

When a fault is finally detected, the next step is troubleshooting it. Most likely, we will find wear debris and all sorts of contaminants inside of the faulty system. The airleaking of the AC system may also become the cause of the malfunction. Fixing the problem will require the use of a flushing system for air conditioners –MS101P. Flushing will remove the contaminations (the old oil above all) and extend the service life of the air conditioner. The procedure also implies a replacement of such AC system components as a condenser, filter-dryer, and an expansion mechanism (a thermal expansion valve and orifice tube).

You are welcome to learn more about AC compressor diagnostics, upgrade your skills, or master a new profession at MSG Equipment training courses.