Rotation angle sensor types. Its general principles

There are a huge number of sensors in automobiles that monitor the operation of various systems. This article describes three existing types of steering wheel angle sensors. These sensors measure the angle of rotation of the steering wheel (shaft) in the range of 1440 degrees, which is equal to 4 full revolutions of the steering wheel. They are usually mounted on the steering column or on the steering rack distributor. In total there are 3 types of such sensors, it is: potentiometric or resistive, optical and magnetoresistive. Let's take a closer look at these types:

Potentiometric sensor. This is in the form of a variable resistor or potentiometer. The potentiometers are arranged so that the relative angle between their locations is 90 degrees. This allows the angle of rotation to be determined more accurately, as for each position there are 2 parameters from which the control unit calculates the angle of rotation.

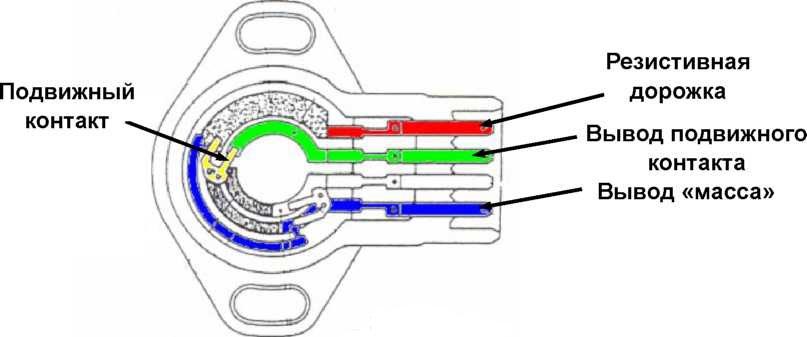

This figure shows the conventional structure of a potentiometric or resistive angle sensor.

The principle of operation of a potentiometric sensor is as follows:

When the driver turns the steering wheel, the movable contact attached to the shaft changes its position and the resistance of the sensor changes. The control unit senses these changes and calculates the angle and side of the turn. The electric power steering starts to increase and help the driver steer the car.

The disadvantage of this sensor is the presence of sliding contacts, which is a less reliable design compared to other types of sensors.

Optical sensor. Consists of an optoelectronic pair, an encoder disc and a full speed control unit.

When the steering wheel is rotated, light from an infrared LED hits an optical receiver (photoresistor) through an encoder disc. Voltage pulses are generated in the sensor circuit and the control unit calculates the direction and angle of steering wheel rotation based on the received data.

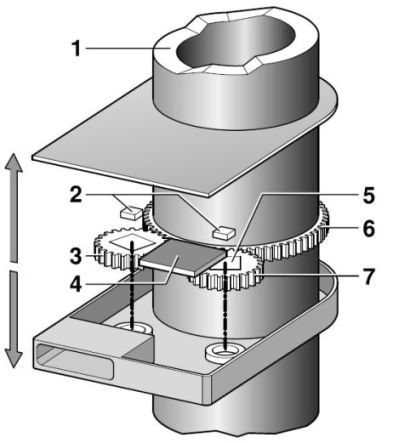

Magnetoresistive sensor. The most complex of those presented. There are anisotropic magnetoresistive sensors in the design of this sensor. The electrical resistance of these sensors changes from exposure to an external magnetic field. This type of sensor calculates the steering angle within 1440 degrees by measuring the steering angle of two gears, which are driven by a drive gear mounted on the steering shaft. The two gears have a difference of one tooth. Thus for each steering shaft position there is a unique pair of steering angle parameters.

1. Steering column; 2. Hall sensors; 3. Gear with nn teeth, measuring; 4. Electronic board; 5. Magnets with permanent magnetic field; 6. Drive gear fixed on the shaft; 7. Measuring gear with n+1 teeth.

Main signs of sensor failure

Turn sensor – is an electromechanical device. There are weak points in its design, it's wiring and some parts. If the protective dust cover breaks, the shaft is covered with rust and the sensor can be corroded. When the sensor is mounted on the rail, dust can get on the surface of the sensor, causing electrical malfunctions and sensor failure.

Signs of failure:

- Yellow or red coloured signals on the instrument panel;

- The steering wheel starts to turn tightly, jerkily;

- The amplifier may amplify stronger in one direction and weaker in the other.

When there is a problem with the steering angle sensor, it is necessary to contact the specialists of the service station, which are engaged in diagnostics and repair of the steering system. Experienced master, with the help of specialised equipment and devices, will be able to detect and eliminate the cause of the breakdown.