Malfunctions of power steering. Causes and identification of failures and repair of power steering units

Thanks to the development of technology in engineering, travelling by motor vehicle is becoming more comfortable not only for passengers, but also, first of all, for the driver. One of the key indicators of comfort in driving a car, along with its dynamic characteristics, is maximum control of vehicle behaviour on the road.

By 2018, the automotive market has already been surprised many times by vehicles with autopilot capability, but exclusively under the supervision of the driver, because the safety of all road users is still not 100 per cent.

Hydraulic power steering

So, the introduction of artificial intelligence in transport management – is an incredible leap into the future, but still in «not cloudless».

Another scenario – creating a car that will be driven by a human and all its actions will be effortless, intuitive and confident. For this purpose, engineers have come up with special mechanisms that have been in use for quite some time, but continue to be improved.

The two most common types of steering power assist mechanism – electric and hydraulic. In our article, we will take a closer look at hydraulic power steering failures and how to fix them.

Service and maintenance of the power steering system

Since the condition of the steering system affects driving safety, special attention should be paid to its maintenance and timely detection of malfunctions.

The list of actions to be taken to maintain the steering system includes, first of all, the following:

- monitor the oil condition;

- control of the condition of the protective elements (dust covers) of the rack;

- care of high and low pressure hoses

It is also important to monitor the occurrence of leaks of working fluid on the nodes and connections of parts of the GSD. If they are absent, you should pay attention to the sound the units make.

What to look out for when driving?

If you turn the steering wheel with the car started or stopped, or overcome any obstacles while driving (kerbs, potholes, «lying policemen») and feel shock in the form of beating, vibrations, etc., it is worth thinking about a possible malfunction of the steering or power steering units.

Signs of faulty steering and power steering units:

- Shocks, knocking and play transmitted to the steering wheel.

- Uneven force throughout the rotation range of the steering wheel.

- The steering wheel position does not correspond to the angle of rotation of the wheels.

- Intermittent «snags» on the steering wheel.

- Knocks in the area of the front axle, transmitted by vibration to the steering wheel.

- The steering wheel returns to the neutral position at the end of a corner.

Vane pump malfunctions

In the manufacture of pumps GUR manufacturers lay down a long service life. Therefore, if the pump is properly operated by the car owner, he will serve for quite a long time. For this purpose, it is enough to monitor the amount and condition of liquid in the system, to ensure tightness of connections, to control the tension of the drive belt, and also to protect the pump from overheating.

Table 1: Main breakdowns of hydraulic fluid pumps

| Failure | Causes | Signs | Treatment |

| Loss of mobility, damage and wear of the relief valve | Malfunction occurs if contaminated oil is used or if particles and foreign matter enter the system, if the pump overheats, if the steering wheel is held in the extreme positions for more than 5-10 seconds.  |

When the engine is warm and the ambient temperature is high, the force applied to the steering wheel increases. A pump rumble can be heard at the extreme steering wheel position. | Replace the damaged valve. If the scoring, damage is significant and duplicated inside the valve seat, the unit body must also be replaced. |

| Pump leakage due to wear or damage to oil seals, gaskets and sealing collars | The level of working fluid in the pump reservoir and its lack in the system, overheating of the hydraulic pump or «blown» system is noted. This is often due to corrosion on the pump shaft or incorrect installation. | Signs of leaks, humming, uncharacteristic colour and smell of oil in the tank. | Replace all oil seals, gaskets and sealing collars with new ones. |

| Pump bushing or bearing is worn | Bearing wear occurs if it is subjected to uncharacteristic loads, shocks, vibrations from the pump, uneven pressure on one side. This can be caused by play in the pump mountings, excessive tension in the drive belt. | Gul, also possible leakage, foaming of the working fluid in the tank. | Replace the bearing; if the bushing is worn, the housing must be replaced. |

| Shaft wear |  |

Gul when running, may leak. | Shaft replacement. |

| Rotor-stator | This type of wear is found on pumps that have overheated severely, or have been operated with contaminated oil or lack of oil.  |

Excessive steering effort, insufficient oil pressure in the system, pump hum, oil darkening and foaming. | Replacing the working pair. |

| Wear and tear of the upper and lower working plate as well as the rotor | It is typical for one of the pump plates to run out of oil when the pump has been overheated or operated for a long time with insufficient oil.   |

Low oil pressure in the hydraulic system, blackened oil, or a foul odour. | Replace the top and bottom plates; if the rotor is worn, then it should also be replaced. |

| Rotor blade sticking | «Vane sticking» occurs on newly installed pumps, but also occurs due to the use of dirty working fluid. | Excessive steering effort – «heavy» steering wheel. | Press the accelerator pedal of the car to increase the engine speed to 3000 rpm. Check the condition of the oil, if necessary – change it. |

| Insufficient or excessive tension of pump drive belt, belt wear | Whistling, rumbling, and pressure pulsation in the hydraulic power steering system. | Release the belt tension to normal or replace it. |

All the above mentioned failures are the consequences of careless use of the car, and therefore – the best way to keep the steering serviceable – proper and timely care of its components.

Power steering rack

The most common sign of a broken steering rack – a knocking sound near the front axle, which is transmitted to the steering wheel. Also about the failure of this node can indicate resistance to rotation or uncharacteristic jerks in the centre position of the steering wheel. Often a broken rack will lose power in one position or another. When driving, you may notice that the wheels do not return to a straight position, and their position relative to the steering wheel is of a different degree.

Table 2. The main failures of the rack and pinion with GUR

| Failure | Photo | Signs | Treatment |

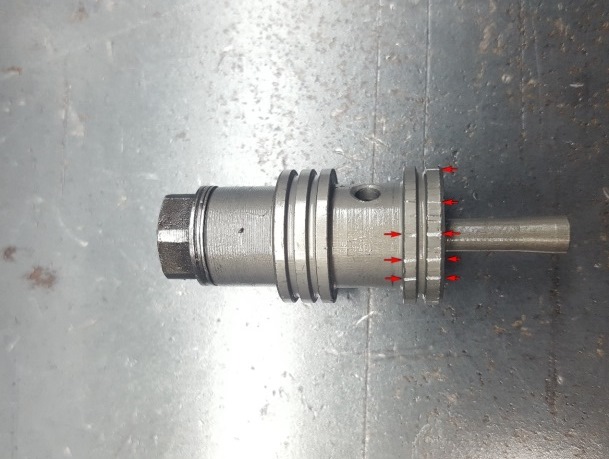

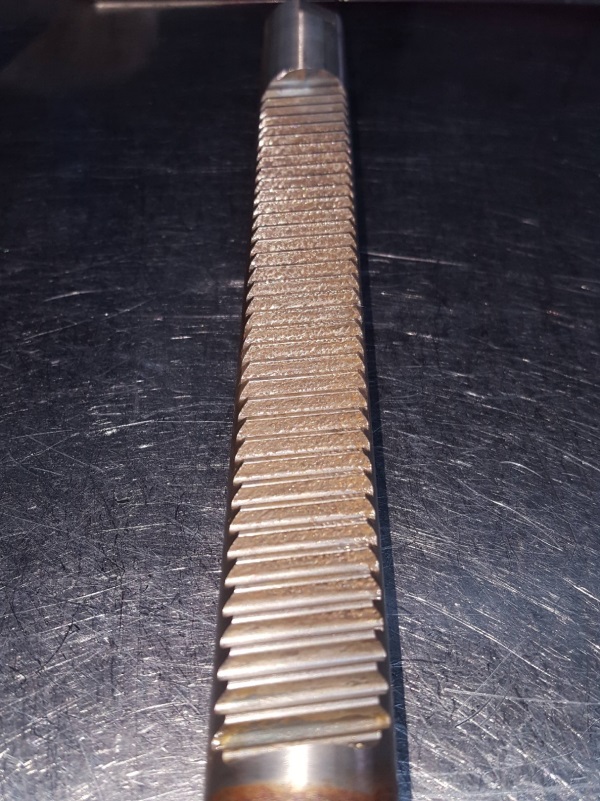

| Corrosion of the stem, toothed sector or working surface of the screw | This phenomenon is most commonand is caused by damaged tie rod dusters.   |

Screeching, seizing, backlash transmitted to the steering wheel. Leakage of the rack, appearance of «heaviness» on the steering wheel. Squeaks, backlash, transmitted to the steering wheel. | Replacing the distributor gear, rack rod, all oil seals and collars. If the corrosion of the rod is insignificant, you can do with grinding and polishing of its working surface. |

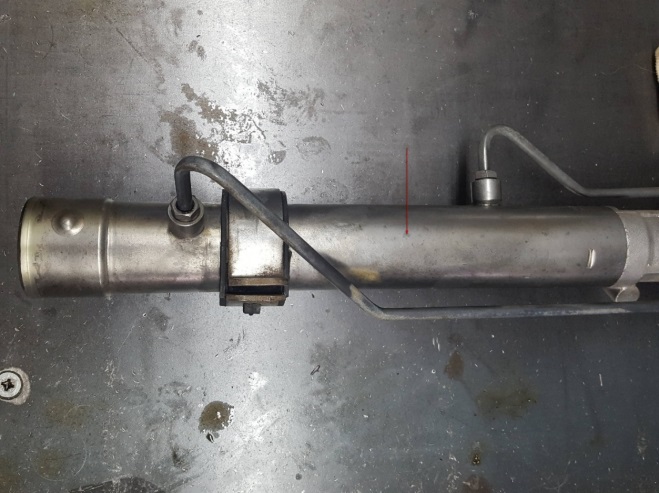

| Ringing in the distributor housing and in the slave cylinder (hydraulic shock) | These defects inside the housing appear after long term use of the rack without changing the hydraulic fluid. These defects inside the housing appear after long term use of the rack without changing the hydraulic fluid.   A similar pattern of damage appears in the hydraulic cylinder. A similar pattern of damage appears in the hydraulic cylinder.  |

Partial loss of power when turning the steering wheel to one side, on a cold engine there may be no steering power at all. Ring wear in the hydraulic cylinder is determined by the unevenness of the force on the steering wheel in its centre position. | Replacing the distributor housing, distributor rail housing, sleeving the working cavity of the distributor housing. Rail housing replacement. |

| Discolouration, damage of teeth in gear: «distributor gear – rod» in middle position | The occurrence of such development is due to the vehicle hitting obstacles. | Knocking, play in the centre position of the wheels, transmitted to the steering wheel. | Install a new stem. |

| Wear of hydraulic cylinder bushings | Wearof the outer bushing is a very common cause of rack knocking, and if ignored, the outer oil seal can wear out as a consequence. | Rack knocking, leaking from the support bush side. | Replacing the bushing and oil seal. Replacing the bushing and oil seal. |

| Rail rod bend | Causedby the front wheels hitting obstacles. | Difficulty or inability to turn to either side.Shocks and squeaks. | Replacing the stem. |

| Torsion twist | The steering and wheel angles are unequal, the steering wheel is too sensitive. | Replacing the gearbox shaft assembly. | |

| Wear and tear of the rail mounting silent blocks | The car drives, throws sideways, vibrations in the steering wheel. | Replaced the silent blocks. |

We have tried to cover the maximum of important topics that relate to malfunctions of units GUR and their elimination. At the same time, we recommend that any type of maintenance or repair of the car should be entrusted only to specialists who have a wide knowledge base, quality components, specialised equipment and tools.