High-quality cleaning of diesel particulate filters without chemicals and environmental harm

For many years, indifferent people have been fighting to preserve the ecology of our planet. As an example, they have banned lead additives for fuels, banned the use of asbestos in the manufacture of brake pads, introduced emission standards for internal combustion engines and much more.

Diesel particulate filters (DPFs) are an important part of the environmental performance of modern diesel engines. They capture and store particulate matter (soot) from the exhaust gases.

When operating a vehicle with a particulate filter, there are certain problems associated with the standard particulate filter cleaning system:

Incomplete regeneration: if the regeneration process is not carried out in full, e.g. on short journeys in the city, the soot does not have time to burn completely, which can lead to clogging of the filter.

Frequent regeneration: Regeneration sensor malfunctions, engine or ECU faults can lead to incorrect regeneration initialisation, which can result in regeneration occurring too frequently, leading to increased fuel consumption, increased engine wear and can also cause turbocharger failure.

What to do if you have a particulate filter problem?

The following steps are recommended:

What to do if you have a particulate filter problem?

1. Diagnose the system. First, the cause of the clogging must be determined. Without a complete and thorough diagnosis of the vehicle, it is pointless to take any action on the particulate filter. If the cause of the particulate filter's rapid clogging is not eliminated, even if a new filter is installed, it will also clog quickly.

2. Eliminate the faults that cause the particulate filter to clog quickly. Faulty pressure and temperature sensors, faulty engine cooling system thermostat, can prevent the regeneration system from working properly. Check and, if necessary, replace all defective elements. It is also recommended to change the engine oil unscheduled, as a clogged particulate filter will allow diesel fuel to enter the engine crankcase, which will degrade the oil's performance.

3. Clean the particulate filter. To do this, you will need to choose the most suitable method:

1) Forced regeneration using special chemistry. Many service centres offer chemical cleaning of DPF without dismantling the filter. In this method, a special chemical compound or several chemically active substances are sprayed into the filter through the opening of the pressure sensor. These chemicals dissolve the soot particles, which helps the soot burn out during the regeneration process.

Minuses of Method 1:

- No opportunity to assess the condition and integrity of the internal structure of the particulate filter.

- Not an environmentally friendly method. During the burnout of the particulate filter, all the chemicals that have been poured into it are released into the atmosphere.

- Unsafe for the engine. Forced regeneration takes about 40 minutes, during which the engine is forced to run at higher speeds and the car is stationary. Such a mode of operation of the engine with insufficient cooling is clearly not in its favour and there is a possibility of its complete failure.

2) Flushingon a bench with a special chemically active solution pre-soak. A fairly common way to remove soot from the filter. In this method of washing the particulate filter is dismantled from the car and a chemically active cleaning solution is poured into it. After a certain period of time the filter is washed with water using a special stand. The chemically weakened soot is washed out of the filter with a stream of water.

Minuses of the 2nd method:

- Service station workers are forced to come into contact with chemically active and hazardous substances.

- Not an environmentally friendly method. All waste water after flushing requires a special method of disposal. No filters can separate the chemistry from the water.

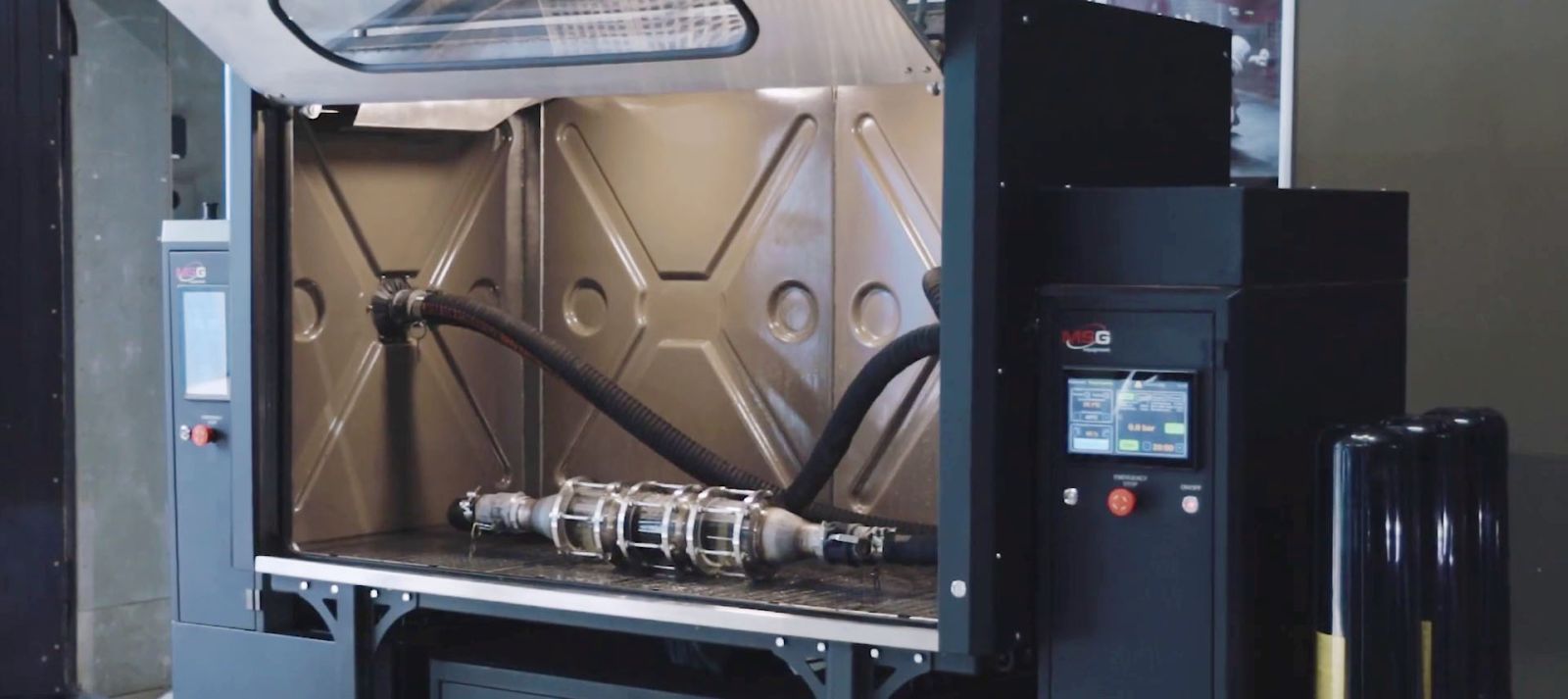

3) Closed loop particulate filter washing with fluid flow change on innovative DPF cleaning equipment. This, the most effective way of cleaning the particulate filter is realised in complex MS900. Cleaning of particulate filter by MS900 complex is carried out by warm water flow in a closed cycle with periodic change of flow direction. Changing the washing flow promotes effective separation of soot and ash from the filter walls, and shock impulses of compressed air strengthen this effect. This approach allows the particulate filter to be cleaned quickly and efficiently without the use of chemical detergents.

Minuses of the 3rd method:

- There is no possibility to wash the particulate filter, which got into the engine oil due to engine malfunction. Cleaning of such a filter without using chemical cleaners is impossible.

4) Filter replacement. In extreme cases, if the internal structure of the filter is damaged, it is necessary to replace it with a new one.

Filter replacement.

Misconceptions of the 4th method:

- High cost.

The particulate filter is an important part of the emission control system, and its proper functioning is critical to maintaining environmental regulations and engine performance. It's also important to take care of our planet and when servicing DPF filters, applying timely equipment that:

- has an efficient washing method;

- has a low cost of washing;

- has the ability to wash particulate filters, both cars and trucks;

- has a short time to clean the particulate filter;

- convenient to use;

- safe for the environment;